CNC Milling Machine 終わりました!!

Apr. 22, 2023

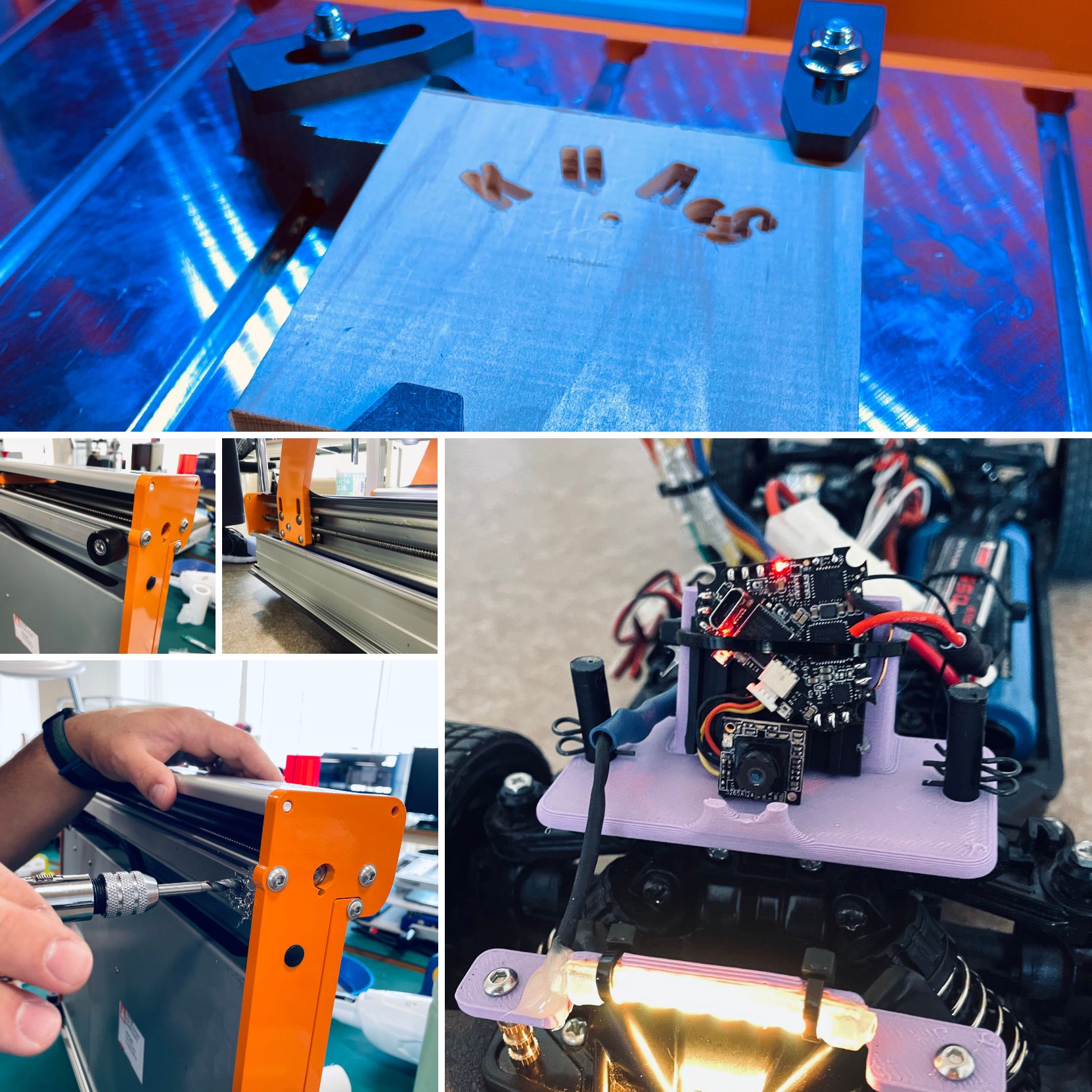

Spent the morning of Saturday assisting Thomas with the assembly of the CNC Milling Machine. Thought it was supposed to go smooth now that we had got the proper screws for securing the rubber feet. But like they say, nothing ever goes as planned.

The screws were quite wiggly, turned out the holes were the reason why. One of the holes even turned out to be stripped, and it came that way from factory! Maybe that’s why the manual made the suggestion of using double-sided tape (?!) to secure the rubber feet instead.

The screw holes were of M6 size. So we borrowed a Hand Tapper from the Machine Workshop and tapped M8 holes there. Thomas let me do one of them, and that’s how I tapped a hole for the first time in my life haha. Then we got some M8 screws from the store which again didn’t work as the extra length was getting in the way of the axes and the store didn’t have anything shorter. So we used some washers to increase the spacing and that did the trick.

Finally, we greased the rails and the ball-screws and finally got a g-code started. It was supposed to engrave KUAS and EWS on the piece of wood, but due to some issue with the file it tried to engrave S twice. We’ll get to it maybe next weekend or the next time we don’t have assignments breathing down our necks.

But yeah, the CNC machine has finally been assembled. It’s been a great learning experience so far, やった!

On other news, I broke the camera mount of my RC car. Time to make a reinforced design.